Editor’s Note: Since this Smith & Wesson M&P Shield review was written, the compact pistol has become one of the best selling handguns in the nation. Recently, the company announced it would be adding the latest M2.0 enhancements to the pistol to make it an even better gun.

The recently introduced M&P Shield, a semi-auto, striker-fired, polymer and steel pocket pistol by Smith & Wesson, should be a winner.

I liked the gun from the time I first handled it right through two range sessions, with about 200 rounds of mixed brand, bullet weights and power 9x19mm ammo (fired by Irv Gill, Ted Murphy, Joe Mulligan and me). Ted holds multiple Master Class ratings in the International Defensive Pistol Association (IDPA). Irv and Joe, who rarely compete in IDPA matches, are ranked Sharpshooter and are quite skilled with the defensive use of either a semiauto or a revolver.

There were no malfunctions caused by either the gun or the shooters. Furthermore, all of us agree that the gun simply feels good in handling and shooting. For me, I see that, with the M&P Shield, S&W strikes all the right notes – those necessary and those desirable – without adding any baggage.

Features

The M&P Shield is a 19 ounce, striker-fired, semiauto chambered for either 9x19mm or .40 S&W and holds seven or eight rounds of 9x19mm and six or seven rounds in .40 S&W.

The stainless steel slide and 3.1″ barrel have the Melonite treatment and are black in color, as is the polymer frame and all small parts.

The frame width is .95″ with a slide width of one inch. The overall length is 6.1″ while its height comes in at 4.6″. The MSRP is $449.

There’s a manual thumb safety at the top left side of the frame, with the takedown lever above the trigger guard. The slide catch is rearward of this and the magazine catch is behind the lower rear of the ample, rounded trigger guard.

The Shield uses a staggered cartridge design which allows more capacity at the (minimal) cost of a slightly wider frame, but still keeping the frame’s length as short as possible.

Two magazines are supplied – one flush fit (seven rounds) and the other having an extended body (eight rounds). Both have identical removable polymer base plates.

The extended magazine wears a polymer “collar” which fills the otherwise open area of the magazine where it protrudes from the frame. The collar is a press fit.

(Ed. note: The extended magazine sleeves and base plates have caused many people problems. Paul Carlson of Safety Solutions Academy came up with a fantastic solution called the MagFix. It eliminates the problems of the sleeve moving up and blocking a reload. Additionally, it helps with the magazine dropping free. For more information, read my Shield MagFix review.)

There are witness holes on both sides of the magazine bodies, numbered three to seven or three to eight.

The top of the slide is flat with rounded edges. A visual loaded chamber indicator is countersunk into the rear of the chamber hood and the forward upper edge of the breech face. S&W terms this the “Type 1 Indicator.” There’s also a “Type 2 Indicator” which is a similarly positioned moveable arm that raises above the slide when a cartridge is chambered. The reason for the two different types is that some states mandate a tactile loaded chamber device. Such laws sometimes also require a magazine disconnect which is provided where such laws apply. These were not present with this sample.

Sights

The three white dot sighting system affords a good sight picture. Sight adjustment is done with the front sight and for windage only. The sight must be moved laterally in its dovetail slot. The rear sight body is shaped to allow snag-free removal from a pocket, a purse or a holster and the square sight notch, coupled with the squared up front sight, allowed for good sighting. The gun has a sight radius of 5.3″.

The ejection port is open across the top of the slide and almost completely down the right side. An ample external and spring-powered extractor sits at the lower right rear of the port. Six scalloped and forward-leaning grasping grooves are beneath the rear sight area. A passive firing pin safety is also in the slide.

The slide is of two thicknesses, with the upper, more narrow portion running from the top to almost the bottom edge. This narrow area extends back to just above the frame-mounted slide catch. The lower forward edges of the slide face are angled inward which helps in holstering the pistol.

The striker retaining backplate is nicely pebbled, reducing thumb slippage if you are trained to press on the rear of the slide while reholstering.

If you have one of these pistols, make sure you check out the M&P Shield holster list at GunsHolstersAndGear.com. There is a full rundown on all of the carry rigs currently on the market for this pistol.

The slide’s left side is marked M&P 9 Shield up-front and has the S&W logo at the rear, just forward of the six scalloped and diagonal grasping grooves. Roll marked on the right front side is “Smith & Wesson, Springfield, MA USA.” The white lettered warning, “CAUTION CAPABLE OF FIRING WITH MAGAZINE REMOVED,” is beneath the ejection port. The caliber designation of 9x19mm is stamped “9MM” on the chamber hood. The gun’s serial number is at the top left of the grip area of the frame.

Controls

On the frame, as previously mentioned, there are three operating controls – the horizontally grooved disassembly lever, the slide catch and the manual thumb safety – on the upper left of the frame. Well worth noting, the manual thumb safety can be activated even with the trigger pulled and not reset. The M&P Shield can be disassembled and reassembled with the manual safety in either position. There is no visual indicator of the safety’s status. The ejector is on the lower left side on top of the frame. The slide travels on four rails or metal inserts which are part of the trigger group.

The trigger reset is short compared to others of this type. There are two “clicks.” The first occurs right as you ease up on the pulled trigger; then, the second and much more distinct click is heard and felt as the trigger is allowed to go further forward. This is the striker and sear resetting. Another shot may now be fired without any further forward trigger movement.

The trigger is a pivoting design and is in two sections – upper and lower. The two are part of the drop safety (often referred to as a trigger safety); the purpose of which is to prevent the gun from discharging if dropped on a hard surface. In use, when the trigger is pulled when firing which entails moving the entire trigger, the operation of the safety system goes unnoticed. Factory specifications show trigger pull weight at +/- 6.5 pounds (more on this later).

Grip

The oval and inward sloping magazine catch is at the lower rear of the trigger guard. S&W points out on its Web site that the M&P Shield grip angle (slide to frame) is 18 degrees. The gripping areas are all nicely pebbled. The front and backstrap pebbling is carried over in an arc onto the sides of the frame, on the tip of the magazine catch and onto the lower rear area of the trigger guard. Stippling has even been done to the rear of the collar spacer used on the extended magazine. (Such attention to detail which greatly adds to providing an excellent gripping area is usually only gotten from a custom ’smith.)

The grip area has matching thumb or finger grooves which allow your trigger finger to move closer inward for easier trigger manipulation, as well as serving as a guide for your gripping hand thumb to more easily establish and maintain a solid shooting grip. The concavities also rise up going forward. This raising on the left side then also surrounds most of the magazine catch body to help prevent accidentally depressing the catch.

The backstrap is extended so that, when the flush plate magazine is locked in the gun, the extension supports the rear of the base plate which then increases the gripping area. This allowed me to take a cramped, almost three-finger grip on the gun – along with more of my palm being supported as well – and definitely helped control muzzle flip.

Disassembly & Lube Points

Disassembly and reassembly of the M&P Shield are simple and quite well explained and illustrated on pages 21 through 25 of the supplied instruction manual. The same information for the magazine is on page 27.

The quick version is, after ensuring the gun is unloaded, lock the slide back. Then, looking down into the ejection port and below the ejector and left side of the breech face (slide directed away from you), you should see a bent, narrow, flat bit of yellow-colored metal pointed upward along the back wall of the frame.

This is the Sear Deactivation Lever. With a small tool (or your finger, if it will fit), push this lever forward to a horizontal position. Next, pull back slightly to release the slide catch and simply move the slide assembly forward and off the receiver.

The slide assembly comes off without resistance since the captive dual recoil spring needs no compression while doing this. The spring does need only slight compressing to lift it off the barrel which then comes out down and to the rear of the slide.

Reassemble in reverse order while noting that you don’t have to fumble with the Sear Deactivation Lever to move it back into place, as inserting a magazine does so.

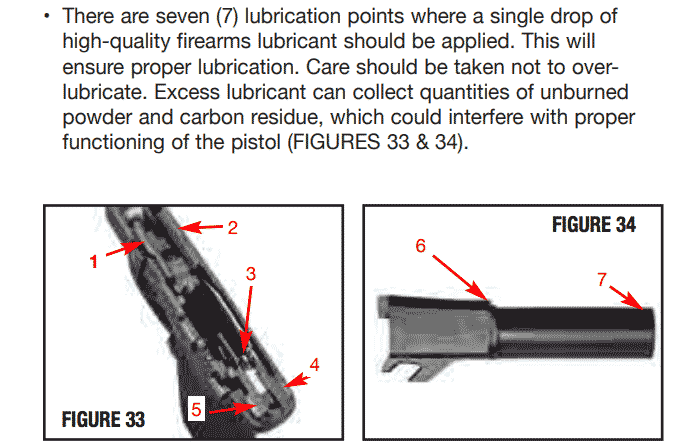

Very important is how and where to lubricate the gun. Seven drops of oil are all that is needed. Illustrated instructions for this are on page 24 for M&P Shield lube points. (NOTE: The striker channel should be as dry and oil-free as possible.)

Range Results

Ted and I met to run the M&P Shield at a local gun club. Ted was greatly interested, as he’s been examining pocket 9mms for hot weather use, while I was somewhat apprehensive. My concern was what sort of accuracy I’d get because, when dry firing the gun, I found I had to very much “lean” on the trigger just as it hit its breakpoint. The trigger pull measured at 8.25 pounds using a Chatillon gauge. Take-up was not a problem, but trigger overtravel looked to be, despite the fixed overtravel stop within the trigger guard.

Ted and I used Winchester White Box 115- grain FMJ and Federal Premium 147-grain HP Hydra-Shok ammo. Circumstances were such that we had to shoot at 12 yards. We shot seated with arms supported on the shooting bench. I found my sights snapping left or right or both with the same shot. That’s not good for accurate shooting – and it wasn’t.

I kept getting two or three hits together, then two or three shots wide left or right. Finally, I had one group of 2 5/8″ using the Winchester 115-grain FMJ ammo and called it quits. Ted took over and using the Federal 147-grain Hydra-Shok ammo started well, but stacked his hits vertically, with his best group measuring at 3 1/4″. We both called it a day.

He commented that the white dots in the sights were distracting. I asked about the trigger weight and trigger overtravel. He said they were a bit bothersome but manageable. The sights or, more correctly, the white dots in the sights were the problem. Normally, I black them out (I find blacking out the rear two dots helps in precision shooting), but didn’t this time as I hadn’t taken any photos of the pistol and didn’t want to mess up the nice white color of the dots.

Later, while setting up to take the photos, I checked the trigger pull results one more time and was surprised to find the pull weight now at an even seven pounds. A few days later, after doing the studio work, I went back to the range, this time with the rear white dots blackened. I also met with Irv and Mulligan and asked for their take on the new gun.

Back Again

This time, we were able to set up at 15 yards. Initially, we shot up a mixed bag of ammo, including Remington and Federal 115-grain JRN, some PMC 124-grain JRN, Remington 147-grain Bonded JHP Golden Saber and Irv’s 124- and 147-grain JRN lead and 124-grain JHP reloads. My best group was five rounds into two inches at 15 yards, of which I was quite proud for a few minutes – until Joe, using some of the Winchester White Box 115-grain loads, put seven rounds into a three to four-inch group at the same distance using the head box of a Warren IDPA training target as his aiming point and did so shooting two-handed and standing. Irv then quietly filled the extended magazine with his lead reloads and overlaid Joe’s hits with eight rounds. They both commented favorably on the Shield.

Later, I again measured the trigger pull which now breaks at the factory specified 6.5 pounds. It appears that while this sample 9mm Shield did not need a break-in period (nor is such recommended by S&W) and we had no malfunctions, its trigger pull certainly benefited.

Final Thoughts

I think – in fact, I’m 99% sure – the S&W M&P Shield is a winner. The final testing will be to shoot lots of rounds and see what, if anything, fails, stops, won’t work or falls off before crowning the Shield (talk about mixing metaphors). My best guess is the worst that will happen is a cross pin or two will “walk” due to frame flex from recoil, as such pins sometimes do in other existing polymer frame pistols.

In hindsight, when Smith & Wesson chose to label its fixed sighted K-frame revolver “Military and Police” (more commonly now known as “M&P”), it was farsighted to be sure, as the military and the police overwhelmingly chose it for a good portion of the 20th century. Dubbing this new M&P pistol “Shield” so, too, indicates its audience and purpose – the legally armed, for personal protection.

Recommendations

Here are a number of recommendations and resources for the M&P Shield you might want to check out:

About the Author: Upon receiving his BS degree from Carnegie Tech and completing service as a Special Agent in U.S. Army Intelligence, Walt Rauch was a Special Agent with the U.S. Secret Service and an Investigator with the Warrant Unit, First Judicial District, PA.

Rauch is also a writer and lecturer in the firearms field. He is published regularly in national and international publications.

This article is a contribution from articles and gear reviews for the patrol officer. P&SN is a valued supporter of BlueSheepdog and the Blue Crew.